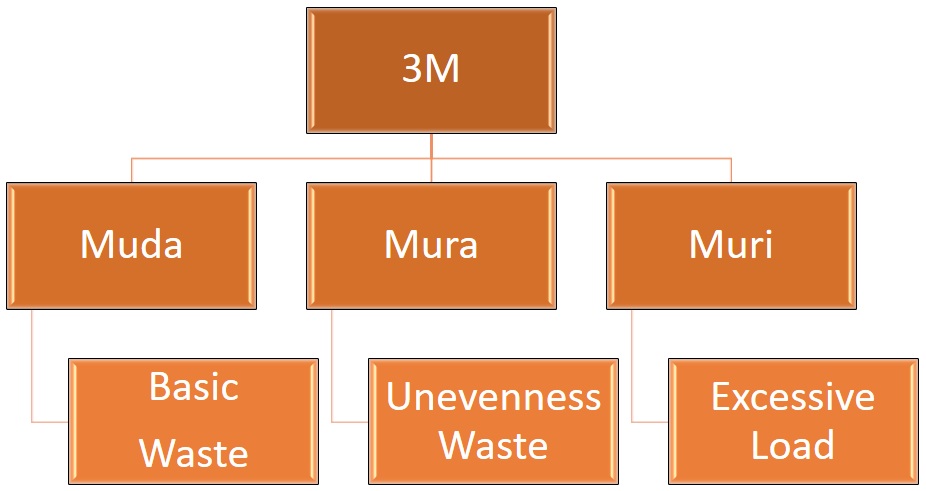

3M Waste

In lean manufacturing, one of the main aspects is to reduce waste and increase productivity. For this reason, you should be familiar with different kinds of waste. One common term used in factories is known as 3M wastage. This term originates from Japanese words that refer to the three broad categories of waste found in a factory: Muda, Mura, and Muri. In English, these are known as Basic Waste (Muda), Unevenness Waste (Mura), and Excessive Load (Muri). Properly understanding these types of waste is key to implementing a successful lean manufacturing process.

Muda (Basic Waste)

Muda means non-value-adding activities that create problems in the production line, disrupting the continuous flow of processes and potentially stopping production. In a Kaizen event, one basic task is to identify these non-value-adding activities at the production site. For example, in a stitching line, if the first two parts of a shoe are glued and then stitched, but it is found that stitching without gluing meets customer quality requirements, the gluing step is considered non-value-adding.

Mura (Unevenness Waste)

Mura means irregularities or inconsistencies in the production process that obstruct continuous production. In a Kaizen event, we aim to eliminate this type of waste. For example, if a stitching machine is not working properly, making it hard for the operator to work smoothly, this irregularity is a common issue in the production line that needs addressing.

Muri (Excessive Load)

Muri means stress, pressure, tension, and difficulties in the production process. In a Kaizen event, we need to reduce or eliminate Muri. For example, one of the hardest operations in a stitching line is making the collar foam of an upper. If the industrial engineering standard time for this operation is 140 seconds but an operator needs 280 seconds to complete one pair of uppers, we first need to check the operator’s skills. If no problem is found, we can add one more person to reduce the operator’s stress.