Lead Time (LT)

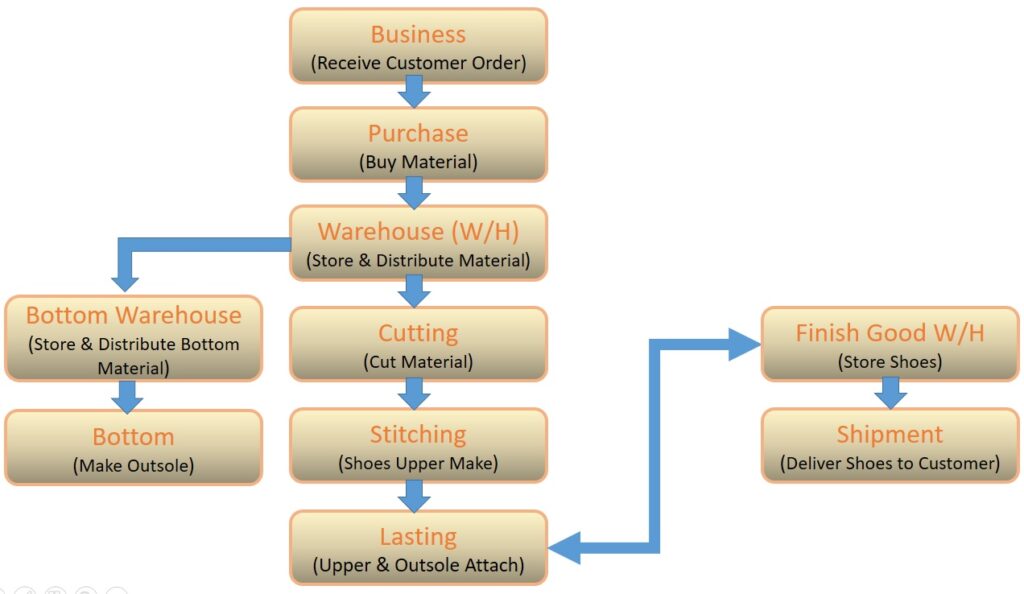

Lead time is one of the key factors of Lean Manufacturing. The number of days needed from placing a customer order to delivering the product to the customer is known as Lead Time (LT). Let’s go through an example with the help of a production flow chart diagram to better understand Lead Time.

After placing a customer order, the purchase department starts to buy material. Let’s assume each section’s finish time is as follows:

Purchase – 30 days to receive all materials

Warehouse – 3 days to store materials

Bottom warehouse – 1 day to store bottom materials

Bottom – 10 days to finish outsoles

Cutting – 7 days to cut all materials

Sewing or stitching – 15 days to finish making uppers

Lasting – 7 days to make complete shoes

Finished goods warehouse – 2 days to store shoes and prepare for shipment

Customer receives the product after 20 days

Now, the lead time for this product = 30 + 3 + 1 + 10 + 7 + 15 + 7 + 2 + 20 = 95 days.

In this way, you can easily determine the lead time of a product. Remember that lead time can vary from product to product. The buyer sets the lead time based on merchandising and the total process time to complete the product. Lead time is one of the key performance indicators in shoe manufacturing because the buyer’s order amount largely depends on whether the manufacturer properly follows the lead time.

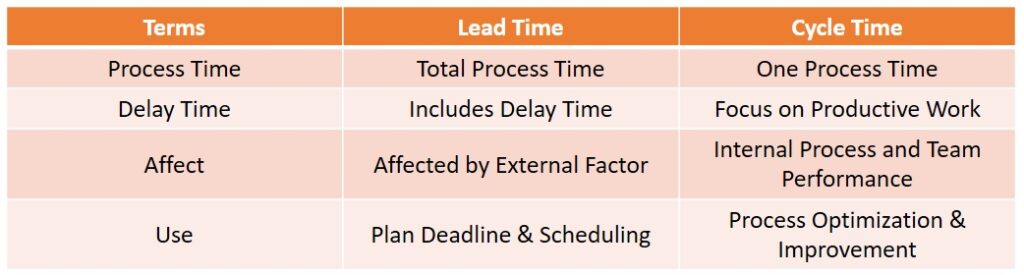

Difference Between Lead Time & Cycle Time