Pitch Time

Pitch time is the ratio of the SAM (Standard Allowed Minute) of a style to the number of operations required to complete that style.

To calculate pitch time, you can use the following formula:

Pitch Time = Available Production Time per Day / Daily Production Target

Where:

Available Production Time per Day is the total number of working minutes or hours available in a day after deducting breaks, downtime, and other non-productive periods.

Daily Production Target is the total number of shoes (or pairs of shoes) you aim to produce in a day.

For example:

If you have 480 minutes available in a day and your target is to produce 240 pairs of shoes, the pitch time would be:

Pitch Time = 480 minutes / 240 pairs = 2 minutes per pair

This means that every 2 minutes, a new pair of shoes should start on the production line to meet the daily target.

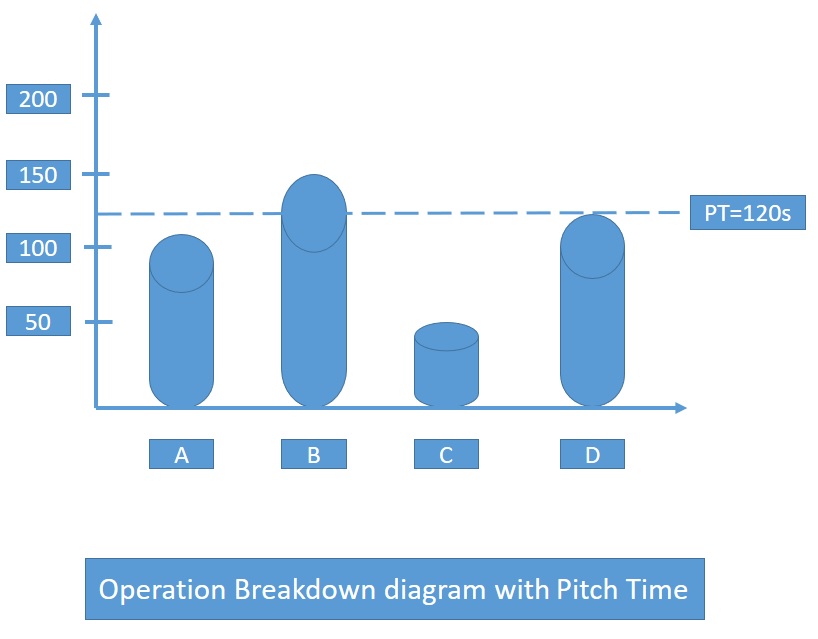

Let’s analyze this diagram:

Operation A: It’s slightly below the pitch time, leading to some idle time, though less than the other non-bottleneck operations.

Operation B: This operation is the bottleneck and will determine the pace of the entire line.

Operation C: At 40 seconds, it is significantly below the pitch time, meaning it will finish much faster and may lead to considerable idle time.

Operation D: At 120 seconds, it is exactly the same as the pitch time, so this operation can achieve the target output without any issues.

Key observation of this diagram:

The line is not balanced. Operation C is significantly faster, leading to inefficiencies. Operation B is the bottleneck of the line. To improve the balance, you could try redistributing work, combining tasks, or even introducing parallel operations for C to better match the pitch time. Balancing the line closer to the pitch time will improve overall efficiency and reduce idle times.

Information needed to make a pitch diagram:

01. Create a list of all operations.

02. Determine the capacity per hour for each operation.

03. Know the production line’s target output.

Pitch time is used for various purposes, such as production line balancing, setting target outputs, and determining machine requirements for each operation.