Kaizen Event on the Production Site

When a production line fails to meet the targets set by Industrial Engineering (IE), it is essential for management to organize a Kaizen event for that particular production line. In this article, we will outline the step-by-step procedure for conducting a Kaizen event:

Step 01: Preparation

First, ensure that all machines and tools on the production line are set up correctly. Print out the operation breakdown or production process for the current style being produced.

Step 02: Detailed Operation Check

Carefully examine each operation. For instance, in a stitching or sewing line, start by checking from upper skiving to upper finishing. Similarly, in an assembly or lasting line, begin with upper and last input to big packing. Ensure that no process is overlooked.

Step 03: Time Gap Analysis

Check the time gaps between the IE standard time and the actual time needed for an operator to complete an operation. If there is a significant difference between the IE standard and actual time, identify the reasons for this discrepancy.

Step 04: Focus on the Seven Wastes

During the process inspection, pay special attention to the seven wastes in the production line. If any waste is identified, note it down and investigate the reasons behind it.

Step 05: Downtime and Machine Condition

Document any downtime observed during the process checks. Additionally, assess the condition of the machines to ensure they are suitable for use by operators.

Step 06: Cost Analysis

Based on the issues identified in Steps 01-05, calculate the cost of the current production style to determine if it is profitable or results in a loss for the factory.

Step 07: Improvement Plan

Develop a comprehensive improvement plan based on the problems identified and the cost analysis. Divide this plan into three terms: short-term, mid-term, and long-term.

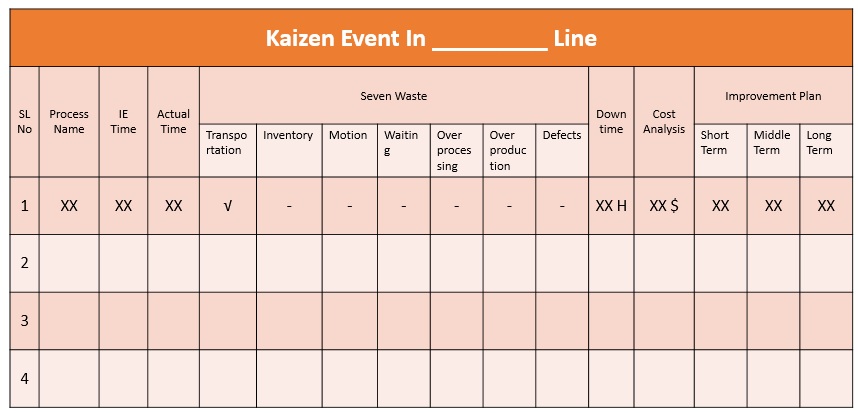

By following these seven steps, you can efficiently complete a Kaizen event on a production line. A Kaizen event format is provided below for a better understanding of the entire procedure. Feel free to add more points as needed. The format of a Kaizen event can vary by factory, but this information will help you identify and solve problems quickly.