Standard Minute Value (SMV)

SMV what does it mean?

SMV stands for Standard Minute Value, which measures the time required to complete a task under defined conditions. Sometimes, it is also referred to as “standard time.” You might wonder why it’s called standard time. The answer is simple: it is calculated based on a time and motion study, which involves analyzing the different operations involved in the manufacturing process. The result is a precise, standardized time, expressed in minutes, that an average worker would need to complete a task.

How to calculate SMV?

The formula typically used is:

SMV = Basic Time + Allowance Time

Basic Time is the time needed to complete each task in the manufacturing process under standard conditions. Industrial engineers are responsible for recording the time of each operation. Basic time varies for different operations because it depends on whether the task can be completed by hand or requires the use of a machine.

Allowance Time is the additional time added to account for unavoidable delays, rest, and personal needs. Since workers need time for these activities, allowances are added to the basic time recorded during the study. Allowance time can vary from one factory to another; it entirely depends on the manufacturer. Before setting the allowance time for each manufacturing process, proper research on production line conditions is necessary. For example, if the restroom is located far from the production line, a higher allowance time is needed because workers will require more time to go and return. On the other hand, if the restroom is situated close to the production line, less allowance time is needed. Similarly, different situations like these must be considered before determining the allowance time.

So, SMV is the combination of basic time and allowance time, which together form the standard time.

Importance of SMV in footwear production

01. Helps to set production targets

02. Improves production efficiency

03. Aids in calculating the accurate price of shoes

04. Provides direction for improving the production line

05. Helps identify the difficulties in making shoes

06. Optimizes labor costs

SMV in the context of Lean Manufacturing

Incorporating Lean manufacturing principles into footwear production involves eliminating waste and improving efficiency. SMV is a key indicator for identifying wastes in the production line because it provides the baseline time for each operation. For example, consider four operation times: A = 120s, B = 130s, C = 70s, D = 100s. To analyze the Standard Minute Value (SMV) of these four operations, we follow a systematic approach:

Step 01: Convert the time for each operation from seconds to minutes.

Operation A: 120 seconds = 120 / 60 = 2 minutes

Operation B: 130 seconds = 130 / 60 = 2.17 minutes

Operation C: 70 seconds = 70 / 60 = 1.17 minutes

Operation D: 100 seconds = 100 / 60 = 1.67 minutes

Step 02: Add allowance time to the above operation times. The percentage of allowances varies depending on the work environment. For this analysis, let’s assume an allowance of 15%.

Allowance Factor: 15% = 0.15

Step 03: Calculate the SMV for each operation.

SMV of Operation A: SMV = 2 × (1 + 0.15) = 2 × 1.15 = 2.30 minutes

SMV of Operation B: SMV = 2.17 × (1 + 0.15) = 2.17 × 1.15 = 2.50 minutes

SMV of Operation C: SMV = 1.17 × (1 + 0.15) = 1.17 × 1.15 = 1.35 minutes

SMV of Operation D: SMV = 1.67 × (1 + 0.15) = 1.67 × 1.15 = 1.92 minutes

Total SMV=2.30+2.50+1.35+1.92=8.07 minutes

Now, compare this SMV with the SMV provided by the industrial engineer (IE) for this operation. Let’s assume the IE’s SMV for operation B is 1 minute. The difference between the actual SMV and the IE’s SMV is 1.5 minutes. This indicates the time gap between the standard and the current situation, ultimately pointing to waste in your production line. Therefore, SMV plays a key role in Lean Manufacturing.

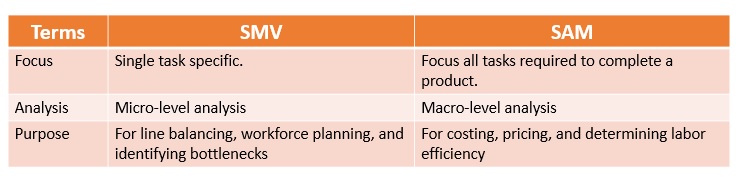

SMV vs SAM

Understanding the distinctions between SMV (Standard Minute Value) and SAM (Standard Allowed Minute) is important for optimizing production processes and improving efficiency. Here’s an overview of each term and how they compare:

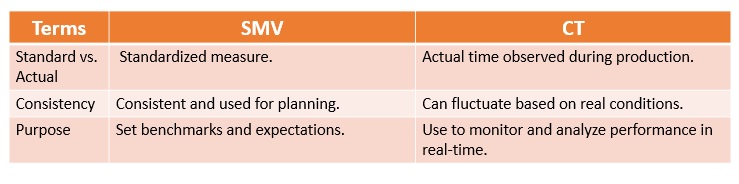

SMV vs Cycle Time

SMV is a theoretical benchmark for how long a task should take under ideal conditions, while Cycle Time measures how long it actually takes in practice. Both are essential for understanding and improving production efficiency but still some gaps between these two terms.